|

|

|

< Back to Index

|

|

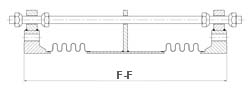

Flanged Universal Expansion Joint |

|

34 inch, 36 inch, 38 inch Nominal Diameter

Notes:

- Rated life cycle at 650°F is 3000 cycles for any one tabulated movement.

- To combine axial, lateral and angular movements, please refer to the how to order section.

- To increase cycle life or movements, please refer to graph on cycle life.

- Rated bellows extension is equal to rated axial movement. Provided bellows is precompressed the amount of design extension. Installed overall length will decrease by the amount of precompression.

- Tabulated values are for tied joints, with butt weld ends. Performance of joints with flanged ends, and unrestrained joints, will exceed tabulated values.

- Maximum test pressure: 1.5 X rated working pressure.

- Bellows rated for 650°F: See catalog flange data for appropriate flange temperature/pressure ratings.

- Pressure thrust load applied to adjacent pipe anchors/equipment when unrestrained expansion joints are used.

|

Size |

Pressure |

Non-concurrant Movements/Spring Rates |

Llateral Movement/Spring Rates |

Axial |

54 |

in.

Overall Length |

66 |

in.

Overall Length |

78 |

in.

Overall Length |

Movement |

Spring Rate |

1372 |

mm

Overall Length |

1676 |

mm

Overall Length |

1981 |

mm

Overall Length |

Movement |

Spring

Rate |

Movement |

Spring

Rate |

Movement |

Spring

Rate |

PSIG |

in. |

lb./in. |

in. |

lb./in. |

in. |

lb./in. |

in. |

lb./in. |

kg/cm2 |

mm |

kg/mm |

mm |

kg/mm |

mm |

kg/mm |

mm |

kg/mm |

34 |

50 |

4.44 |

273 |

6.97 |

129 |

9.56 |

74 |

7.96 |

292 |

3.5 |

113 |

4.9 |

177 |

2.31 |

243 |

1.32 |

202 |

5 |

135 |

2.13 |

1683 |

3.54 |

723 |

5.01 |

398 |

4.5 |

1346 |

9.5 |

54 |

30.1 |

90 |

12.94 |

127 |

7.12 |

114 |

24 |

275 |

1.58 |

4951 |

2.89 |

1856 |

4.25 |

958 |

4.24 |

2699 |

19.3 |

40 |

88.6 |

73 |

33.21 |

108 |

17.14 |

108 |

48 |

36 |

50 |

4.21 |

323 |

6.59 |

152 |

9.05 |

88 |

7.96 |

309 |

3.5 |

107 |

5.8 |

167 |

2.72 |

230 |

1.57 |

202 |

6 |

135 |

2.02 |

1991 |

3.35 |

854 |

4.74 |

471 |

4.49 |

1427 |

9.5 |

51 |

35.6 |

85 |

15.28 |

120 |

8.43 |

114 |

26 |

250 |

1.52 |

5853 |

2.78 |

2194 |

4.09 |

1132 |

4.31 |

2860 |

17.6 |

39 |

104.7 |

71 |

39.26 |

104 |

20.26 |

109 |

51 |

38 |

50 |

3.99 |

379.0 |

6.26 |

179 |

8.59 |

103 |

7.96 |

327 |

3.5 |

101 |

6.8 |

159 |

3.20 |

218 |

1.84 |

202 |

6 |

130 |

1.93 |

2333.0 |

3.21 |

1001 |

4.53 |

552 |

4.52 |

1508 |

9.1 |

49 |

41.8 |

82 |

17.91 |

115 |

9.88 |

115 |

27 |

250 |

1.44 |

6859 |

2.64 |

2571 |

3.88 |

1327 |

4.3 |

3021 |

17.6 |

37 |

122.7 |

67 |

46.01 |

99 |

23.75 |

109 |

54 |

Materials

Bellows: A240-T304. Alternate materials available upon request. Refer to the materials section.

Flanges: ASTM A105.

50 PSIG Series: 125 lb. Lt/Wt FFSO.

For 130-135 PSIG Series and 250-275 PSIG Series: Customer to specify actual flanges required.

Plate flanges and angle flanges available for low pressure systems.

Pipe: ASTM A-285-C.

50 PSIG Series: 0.375-inch wall

130-135 PSIG Series: 0.375-inch wall.

250-275 PSIG Series: 0.500-inch wall.

Liners: A240-T304.

Covers: Carbon steel.

Tie Rods, Hinges, Gimbals: Carbon steel

|