What is a Fabric Expansion Joint?

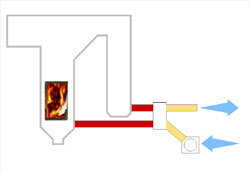

Fabric expansion joints perform a function of compensating for duct misalignment and duct thermal growth typically in power plants and other ducting systems. Fabric expansion joints are found wherever there is a need to convey hot media in low pressure applications such as "in flowing air" and "out flowing gas" in large combustion processes. Fabric expansion joints perform a function of compensating for duct misalignment and duct thermal growth typically in power plants and other ducting systems. Fabric expansion joints are found wherever there is a need to convey hot media in low pressure applications such as "in flowing air" and "out flowing gas" in large combustion processes.

Fabric expansion joints can absorb larger movements than metal expansion joints and do so without spring loads. This is critical to limiting thermally induced stresses in ducting, ducting supports, and related equipment.

How Does a Fabric Expansion Joint Work?

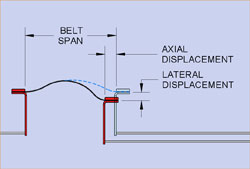

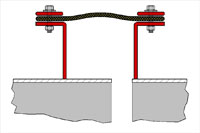

A fabric expansion joint is inserted into a gap in the ductwork where movement will occur. A fabric expansion joint has two main components -- the fabric gas seal and the metal frames. The fabric gas seal is a closed loop, like a belt, with its two edges clamped all around to the metal frames that are in turn connected to the end of ducting. As the ducting moves, the fabric belt deforms. The fabric material must do this without tearing or leaking while sometimes being exposed to high temperatures and/or corrosive media. A fabric expansion joint is inserted into a gap in the ductwork where movement will occur. A fabric expansion joint has two main components -- the fabric gas seal and the metal frames. The fabric gas seal is a closed loop, like a belt, with its two edges clamped all around to the metal frames that are in turn connected to the end of ducting. As the ducting moves, the fabric belt deforms. The fabric material must do this without tearing or leaking while sometimes being exposed to high temperatures and/or corrosive media.

In some instances, additional components such as insulation pillows, accumulation barriers or flow liners are utilized to help protect the fabric material. The following section describes the basics of fabric expansion joint components and how they are designed.

Design Integration for Fabric Expansion Joints

In addition to fabric expansion joints, U.S. Bellows is a major designer and fabricator of ducting. Design Integration is the design, manufacture and shipping of expansion joints integrated into the ducting as a complete unit directly from U.S. Bellows. This enables U.S. Bellows to offer optimum system design and the lowest installed cost. In addition to fabric expansion joints, U.S. Bellows is a major designer and fabricator of ducting. Design Integration is the design, manufacture and shipping of expansion joints integrated into the ducting as a complete unit directly from U.S. Bellows. This enables U.S. Bellows to offer optimum system design and the lowest installed cost.

Design Integration Advantages:

- Elimination of flanged connection gasketing and potential leaks.

- Elimination of the risk of installing sensitive assemblies at the job site.

- Significant costs savings of both manufacturing and installation labor.

- Delivery of the largest "shippable" duct and piping sections to the job site to eliminate as many filed connections as possible, further reducing installation labor.

- Minimize the number of flanged expansion joint connections.

- Allows integration of ducting to serve as expansion joint flow liner.

- Allows expansion joint frames to take the place of duct stiffeners.

- Elimination of labor to install flanged expansion joint assemblies at the job site.

U.S Bellows has considerable experience in design and fabrication of integrated ducting with metal and fabric expansion joints. U.S. Bellows is also very knowledgeable with transportation capabilities for wide and heavy loads and can make firm commitments "up-front" for the largest shippable size and heaviest weight. U.S Bellows has considerable experience in design and fabrication of integrated ducting with metal and fabric expansion joints. U.S. Bellows is also very knowledgeable with transportation capabilities for wide and heavy loads and can make firm commitments "up-front" for the largest shippable size and heaviest weight.

The drawing below shows a cross section of an expansion joint designed to allow the ducting to serve as a flow liner. The joint frame takes the place of a stiffener flange. The complete duct/expansion joint ships as one factory assembled component.

|